Smart Automation

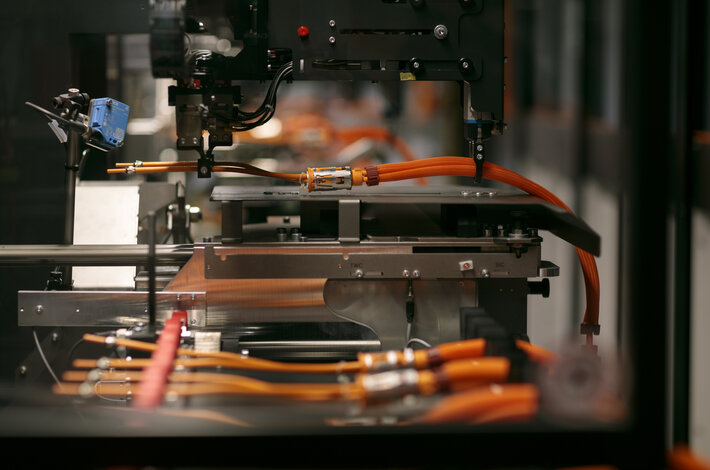

High process reliability, low error rates, stable supply chains, and CO2 reduction –at competitive costs: All of these factors are key requirements for today’s manufacturing of vehicle electrical systems. Our answer: Networked production with a high degree of automation, coherent product design, and intelligent process technology.

Since 2012, we have been successfully automating the manufacturing of low-voltage and high-voltage wire harnesses as series – setting standards for efficiency, resilience, and sustainability in wiring harness production.

From Vehicle Configurator to individual Wiring System

Each vehicle has been uniquely designed in accordance with customer requirements – and the same applies to its nervous system: the vehicle electrical system. This goes hand in hand with enormous variability. For us, this means producing with batch size 1 and precise control of development, production, and logistics in a minimum of time.

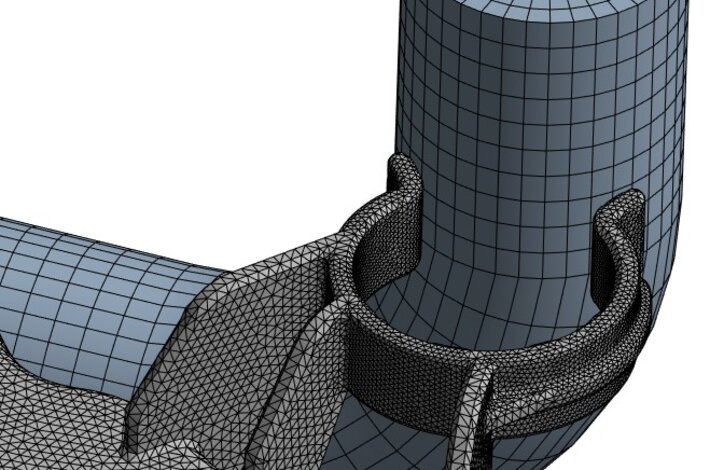

Safety through Simulation

What does future-proof vehicle development mean? At Nexans autoelectric, it starts virtually – long before the first wire is installed. Our innovative simulation processes ensure the quality and reliability of our vehicle electrical systems using digital methods: Quickly, precisely, and resource-efficiently. Whether it is thermal simulation, FEM analysis, or smart installation planning – our virtual prototypes help us to identify risks early and work out the best solutions in a targeted manner.

CREATIVE SOLUTIONS CREATED IN TEAMWORK

Discover – Connect – Implement

In cooperation with universities, research institutes, and industrial partners, we develop new approaches in concrete projects – by openly sharing ideas, embracing creative impulses, and pooling expertise in a targeted manner.

Functional Safety – Safety-Relevant Vehicle Electrical Systems

Safety-relevant vehicle electrical systems combine essential vehicle components and at the same time ensure a stable power and data supply, so that critical safety functions work reliably at all times.

Minimizing transport

In a globally connected world, speed and reliability matter more than ever. For our logistics team, this means reliably supplying customers, maximizing process transparency, and using resources efficiently. With our proprietary logistics tool, which facilitates external partner access at all times, we achieve precisely this: Predictable arrival times, the shortest loading and unloading processes, and flexible responses to unforeseen events. This keeps our supply chain moving at all times – as precise as clockwork.