For us, innovation means challenging existing solutions and developing substantial new ones – across all processes. We are driven by curiosity, creativity, and a clear view of industrial reality. This is how we think and work – in every innovation project. We want to advance technology efficiently, design it sustainably, and implement it economically. For solutions that work in practice and tomorrow’s mobility at its best.

Smart Automation

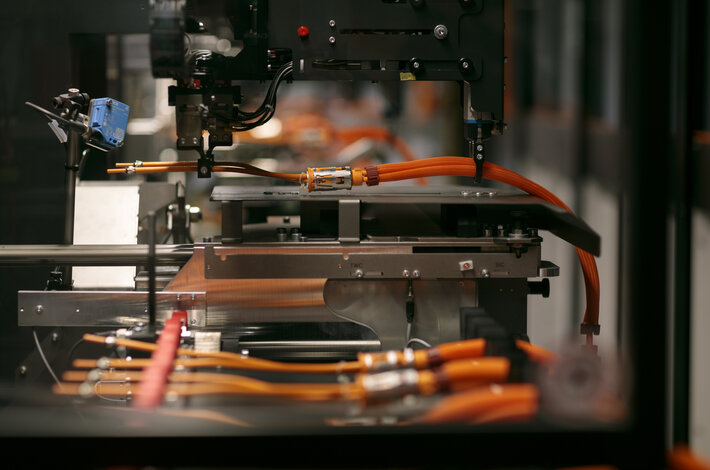

High process reliability, low error rates, stable supply chains, and CO2 reduction –at competitive costs: All of these factors are key requirements for today’s manufacturing of vehicle electrical systems. Our answer: Networked production with a high degree of automation, coherent product design, and intelligent process technology.

Since 2012, we have been successfully automating the manufacturing of low-voltage and high-voltage wire harnesses as series – setting standards for efficiency, resilience, and sustainability in wiring harness production.

Customer-specific Wire Harnesses – from Vehicle Configurator to individual Vehicle Electrical System

Every vehicle is uniquely tailored to the customer’s very own requirements and so is its vehicle electrical system – the nervous system in cars and trucks. Customer-specific wiring harnesses (CSW) have to master enormous variance. For us, this means production with a batch size of 1 and accurate coordination of development, production, and logistics within a minimum of time.

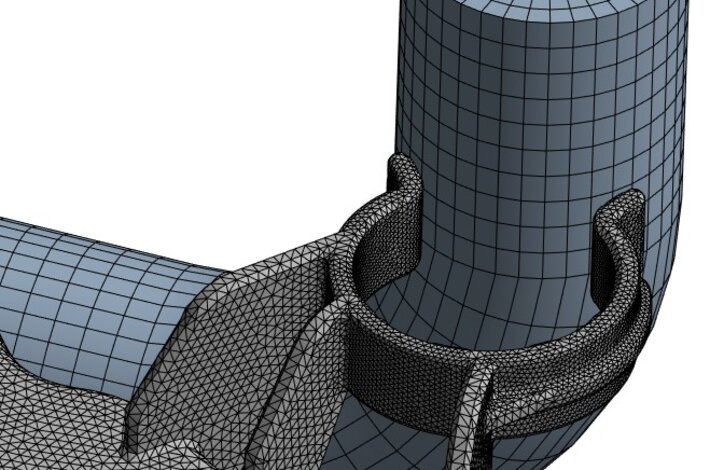

Safety through Simulation

What does future-proof vehicle development mean? At Nexans autoelectric, it starts virtually – long before the first wire has physically been installed. Our innovative simulation processes digitally safeguard the quality and reliability of our vehicle electrical systems: Quickly, precisely, and resource-efficiently. Whether thermal simulation, FEM analysis, or smart layout planning – our virtual prototypes help identify risks early and work out the best solutions in a targeted manner.