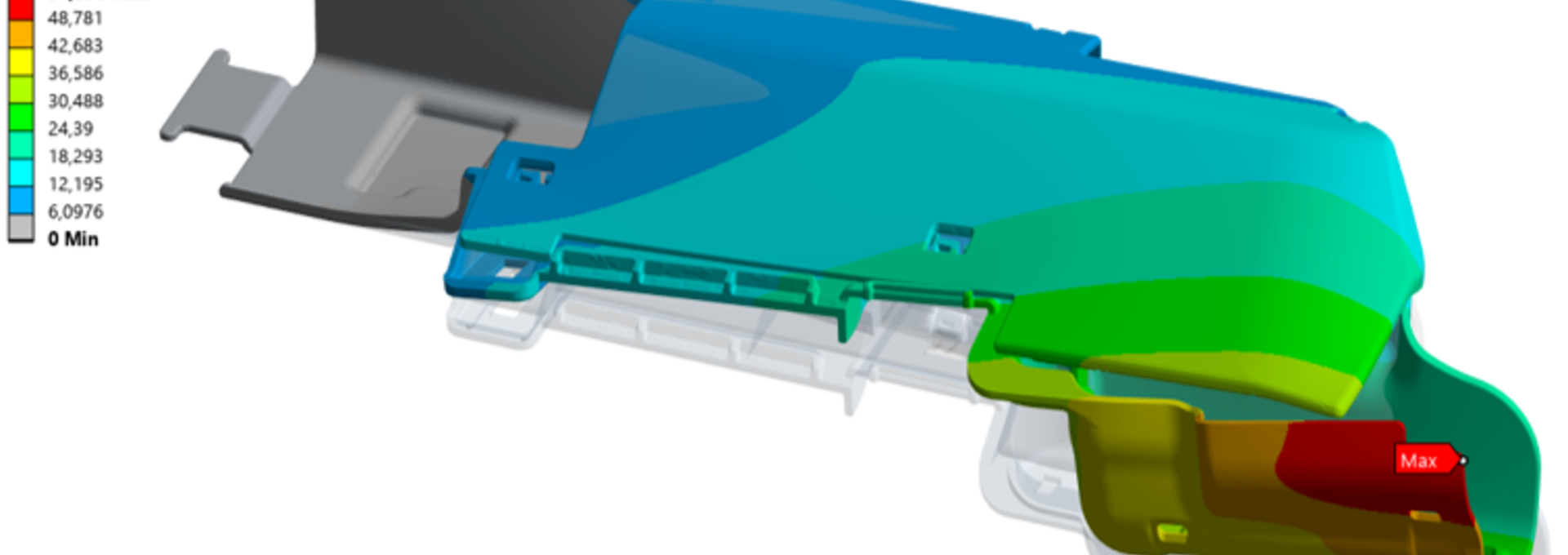

Mechanical reliability is no coincidence – it is the result of forward-thinking development: Using the Finite Element Method (FEM), we already ensure the structural integrity and durability of every component in our wiring harnesses from the development stage.

Whether vibrations, dead weight, or thermal influences: Our simulations provide in-depth insights into potential weak points and help to eliminate them in a targeted manner.

In addition, our FEM simulations enable us to link load conditions and specifically analyze the interaction between thermal and mechanical loads. A detailed temporal load profile allows us to precisely predict the service life and long-term behavior of components using fatigue analyses.

By taking nonlinear material properties – such as deformation behavior – of plastics, metals, and composites into account, we obtain in-depth analysis results. These are crucial for developing robust, durable components that function reliably in vehicles – even under challenging conditions.