Electromobility is changing the world – and we help shaping it. Our high-voltage solutions ensure that electric vehicles charge safely, distribute energy efficiently, and store it reliably.

Fast and safe charging is crucial for everyone who uses their electric vehicle every day. With our solid aluminum conductors as charging cables, we enable just that – while they are significantly lighter than copper solutions.

Our compact and smartly routed wire harnesses for high-voltage storage systems make a key contribution to the performance, safety, and range of modern electric vehicles. They ensure that high-voltage storage systems store energy quickly and safely and make it available as needed.

At the heart of the electrical system is HV power distribution. Our high-voltage distribution units ensure the reliable transmission of energy to all consumers in the vehicle – precisely, safely, and tailored to customer-specific requirements.

Fast and Safe Charging: Facilitated by Solid Aluminum solid Conductors

High charging performance is a crucial factor for the everyday suitability of electric vehicles. This requires powerful charging cables – with increasingly tight installation spaces, higher power requirements, and increasing levels of automation.

Our solid aluminum conductors meet precisely these requirements: High current-load capacities (up to over 800 A) at a low weight, reduced installation space, and efficient processing. Their dimensional stability facilitates the automated manufacturing and assembly in the vehicle. The close parallel routing of the busbars improves EMC behavior – separate, frequently costly, shielding is often unnecessary.

Add-on: With CO2-reduced aluminum and insulation made from recycled plastics, we are making our contribution to decarbonization. Solid aluminum conductors are also used as an "energy backbone" in zonal vehicle electrical systems – for a stable energy supply to power-intensive systems such as driver assistance functions or autonomous driving functions.

Energy Distribution Systems: The Heart of Power Supply

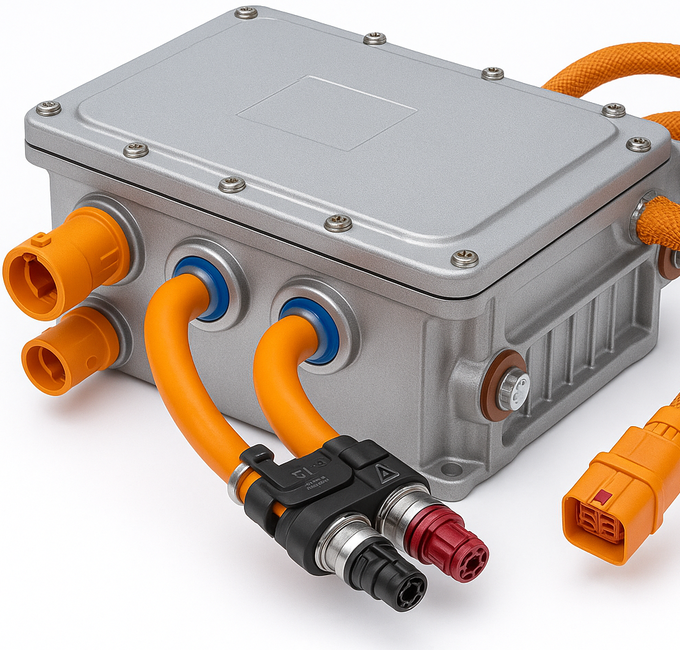

Our HV power distribution unit (PDU) is the central element in the electrical system of electric and hybrid vehicles. It handles the safe distribution of energy from the battery or power electronics to electrical consumers such as heating and cooling systems or drive units.

In addition, it integrates safety-relevant functions – such as protection against short circuits or overloading – and must therefore meet the highest safety requirements.

From the very beginning, we develop our PDUs with a view to service life and vehicle load scenarios. Even in the early development phases, we simulate power flows and protect critical components such as HV fuses accordingly. This allows electrical changes to be directly assessed for service life – an important prerequisite for durable and reliable vehicles.

Validation, simulation, and vehicle testing ensure systematic protection – from the initial drawing to serial release.

A New Generation of High-Voltage Storage Systems: We Ensure Precise Signal and Power Transmission

The high-voltage storage system is the central energy storage system in an electric vehicle – technologically complex and safety-critical. With more than 300 individual wires ranging in size from 0.17 mm² for signal wires to 95 mm² for power supply, its wiring is truly a masterpiece of engineering..

Our wiring harnesses in the battery system transmit power and control signals – reliably, vibration-resistant, and electromagnetically compatible. They must meet the highest requirements: High energy and power density, minimal installation space, long service life, and, above all, cost-effectiveness. We rely on tailor-made designs, robust materials, and a validated development process that covers all phases from concept to series maturity. Production is semi-automated – for reproducible, high-quality results.