Innovation is a key driver for us – for sustainable processes, modern products, and strong competitiveness.

Flexible flat cables (FFC/FLBL) afford clear advantages for signal and data transmission in vehicle electrical systems: They save installation space and weigh and enable highly automated manufacturing. The overmolding of busbars instead of traditional assembly also adds value – through fewer process steps, reduced component variety, and a compact, functionally integrated solution.

That’s how we actively contribute to CO2 reduction along the entire value chain.

New cables in vehicle electrical systems

Our flexible flat cables (FFC/FLBL) offer clear advantages over traditional round cables: Proven to be effective in steering wheels and special applications – or with great potential in future vehicle electrical systems, which is what we focus our development work on.

Thanks to their compact design, precise conductor spacing, and the potential reduction in electrical cross-sections due to their high tensile strength, our flat cables save up to 75% of installation space. At the same time, their large surface area significantly improves heat dissipation allowing for lighter, slimmer power supply cables.

Even shielded and impedance-stabilized versions for high-performance data transmission – such as via Automotive Ethernet – are feasible.

Another advantage: They are ideal for automated production – up to and including full automation. This reduces CO2 emissions and enables significantly more efficient and customer-oriented production.

Whether it is for high flexibility in vehicle doors or as an integral component of future high-voltage vehicle electrical systems: Our flat cables represent a new generation of flexible, sustainable, and smart vehicle electrical systems.

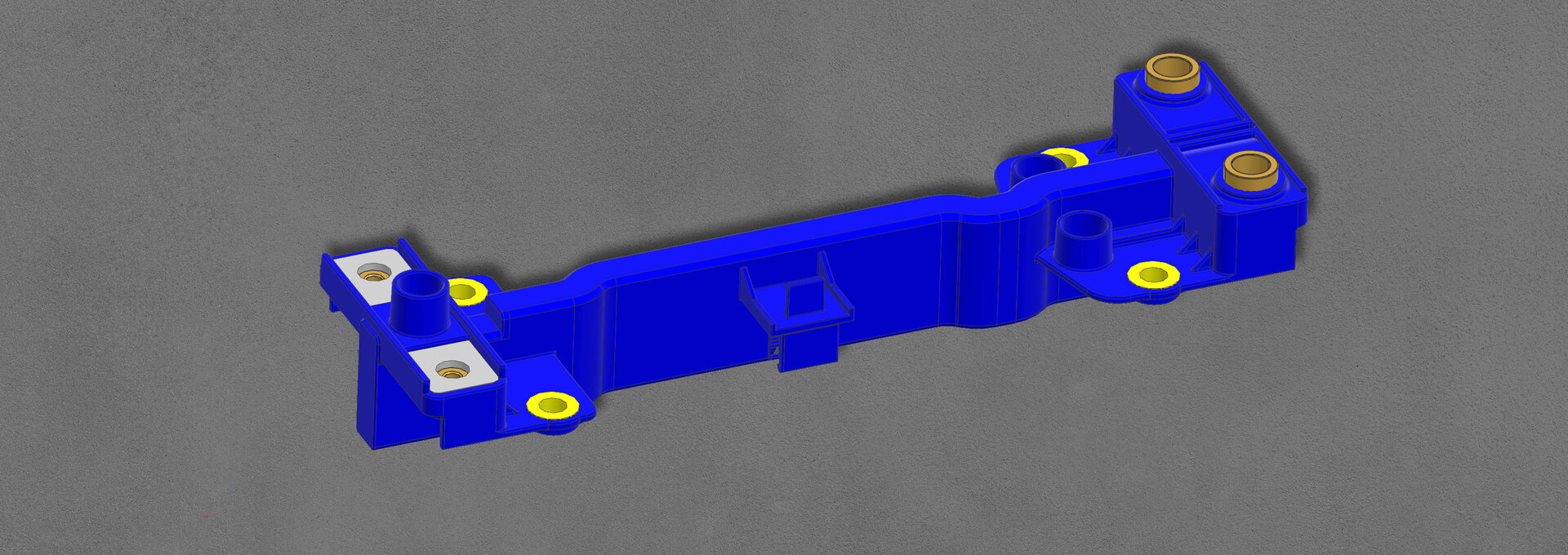

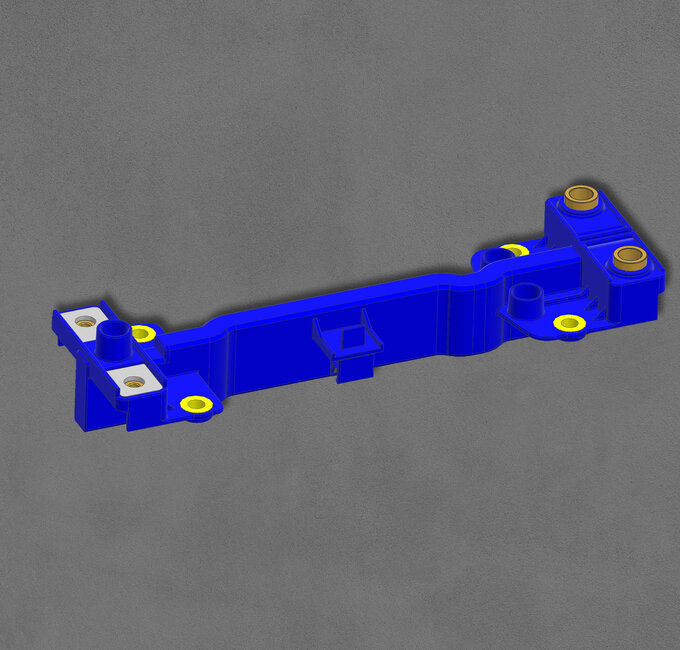

Functional integration through overmolding of busbars

Busbars are the energy backbone of modern vehicle electrical systems – especially in the high voltage range. Instead of traditional assembly with numerous components, we are developing a technology in cooperation with Fraunhofer IMWS: A fully overmolded solution in which all functions are integrated in a single, compact manufacturing step.

This kind of functional integration replaces numerous components and reduces process steps to a minimum. The result: Significantly fewer error sources, streamlined and automated manufacturing, and a resilient, resource-saving value chain. In addition, supply chains are facilitated, installation processes are simplified, and valuable installation space is saved.

In vehicles, overmolding ensures robust insulation, mechanical protection, and high corrosion resistance – for a long-lasting, reliable energy supply. This allows us to create the basis for future-proof vehicle electrical systems with a maximum gain of installation space and minimal complexity.