When space is tight, every millimeter counts – the digital twin makes it visible. By digitizing our components, we take precision and efficiency to a new level: We identify irregularities early on, use limited installation space best, and respond flexibly to individual customer requirements.

Optimized Installation Space Utilization Through Digitalization

For the precise and safe routing of our wire harnesses, we develop individual ducts and guiding elements that are precisely tailored to the available installation space. Already in the prototype phase, we identify these components using 3D scans and convert them into digital models – the basis for all subsequent analyses.

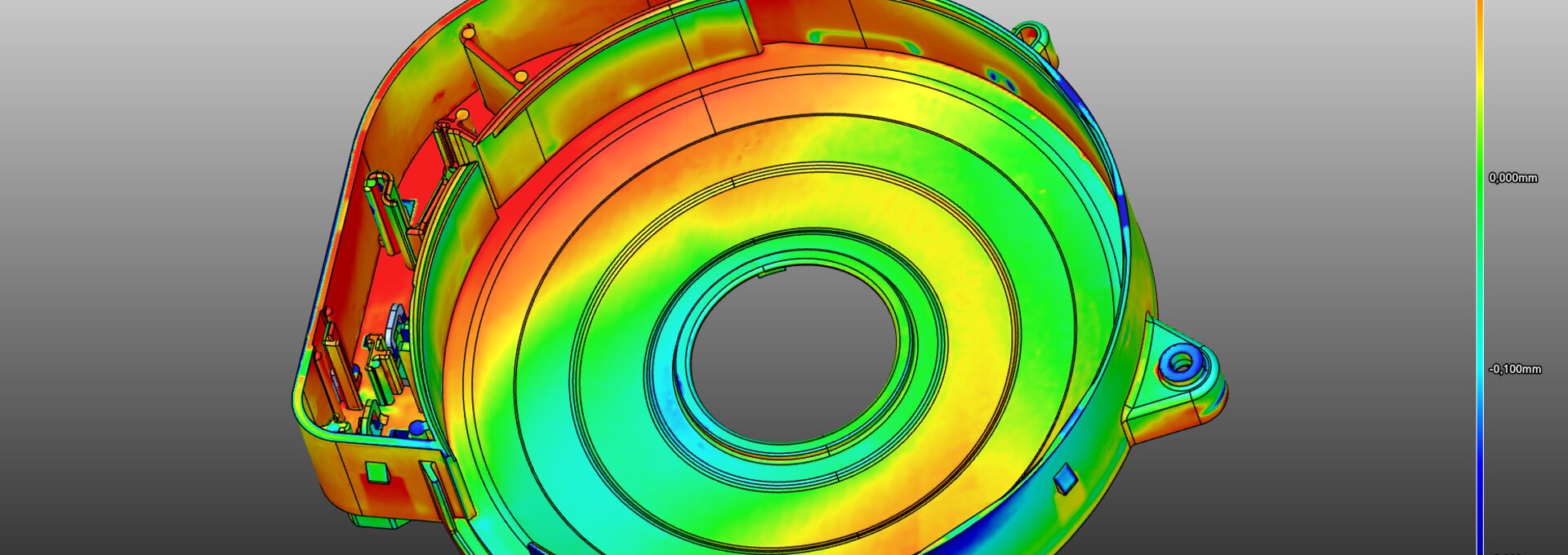

Precision Comparison Using CAD Models

In the next step, we compare the scanned geometry data with the original CAD construction. Color-scaled visualizations show deviations at a glance – providing our designers with a quick, intuitive basis for making decisions for further optimization steps.

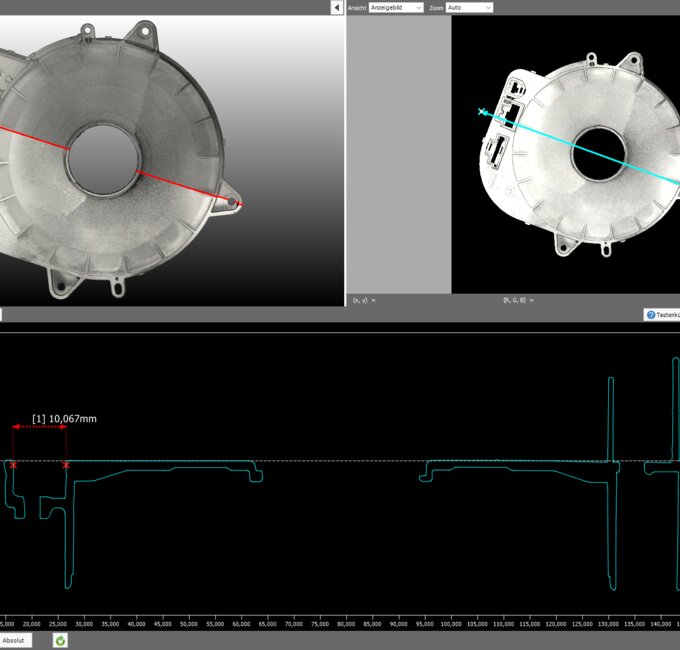

Broadly Applicable Digital Data

Digital data, versatile in use The digital models enable traditional dimensional comparisons as well as automated testing of geometric and positional tolerances according to ISO standards. In addition, the data can be exported for reverse engineering in STEP format and directly processed. The effort required for physical archiving is also eliminated – the digitized components are virtually available at any time.