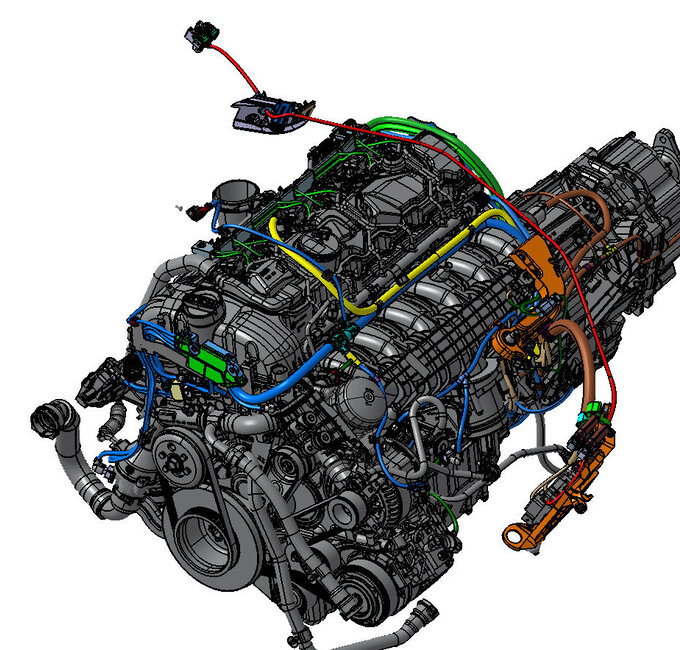

Our engine wiring harnesses are the silent powerhouses of fuel-driven vehicles: They connect electrical and electronic components in the engine compartment all the way to the gearbox – precisely, reliably, and robustly – and ensure optimal energy utilization.

Through targeted further development and the use of innovative technologies, we are able to set new standards even for established products such as engine wire harnesses – for lower emissions, even greater efficiency, and the highest technical quality.

Perfect Engine Management

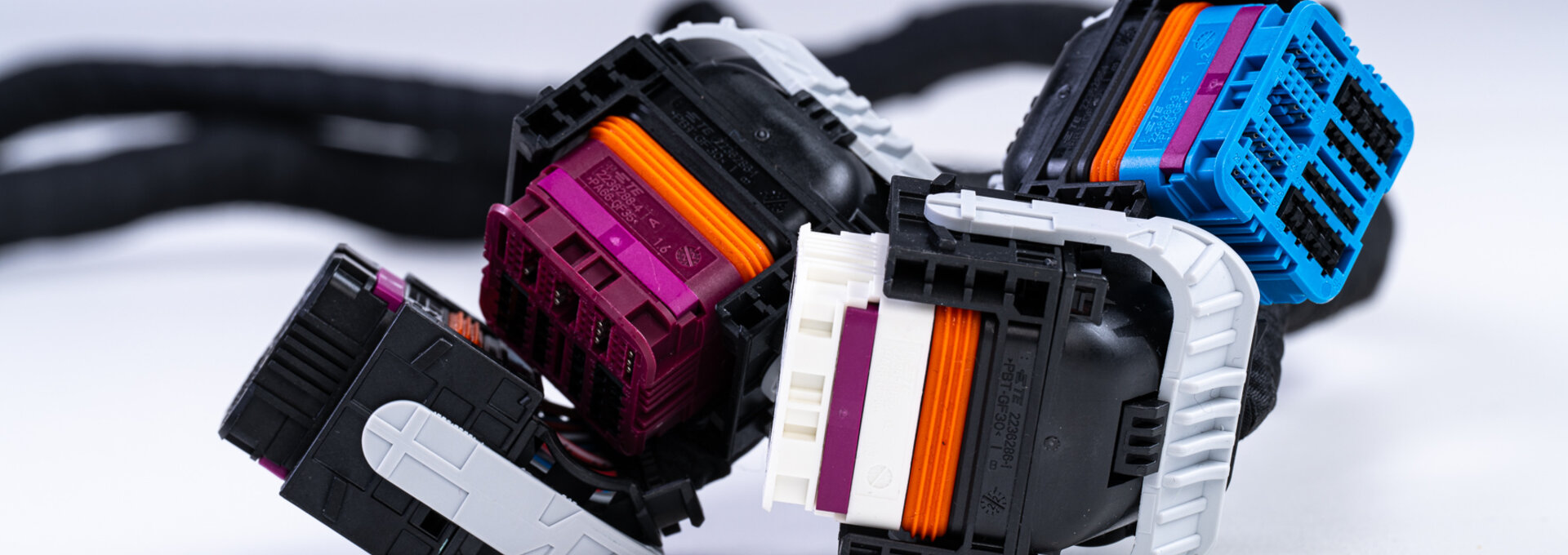

Engine wire harnesses are essential in fuel-powered vehicles for the safe transmission of energy and signals between sensors, actuators, and control units in the powertrain. They enable the precise interplay of all relevant components – even under extreme conditions such as high ambient temperatures above 180°C, humidity, chemical contamination, or continuous vibration.

A typical engine wire cable harness for a mid-size vehicle comprises around 250 individual wires, over 500 contact parts and plug housings, as well as various protective measures such as cable ducts and bandages. All materials and components used undergo defined validation processes before being released for series production – adapted to the respective mechanical, thermal, and chemical

CO2 Savings Through Smart Design

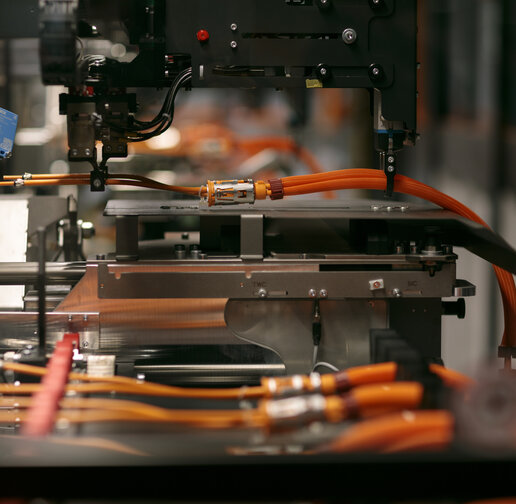

Less weight, efficiently utilized installation space, maximum functionality: These requirements are part of every new project. Space is particularly limited in the engine compartment, while at the same time, demands on power distribution, diagnostic capabilities, and environmental compatibility are increasing.

Our engineers resolve this conflicting objectives with space-optimized geometry, carefully designed wire cross-sections, and the integration of miniaturized plug systems and components – functional, efficient, and reliable.

ENGINE WIRE HARNESSES FOR A WIDE RANGE OF VEHICLES

Engine wire harnesses vary considerably in design, complexity, and technical specifications depending on the vehicle type, drive architecture, and performance requirements.

Nexans autoelectric develops and produces solutions for a wide range of applications – from compact city vehicles and high-performance motorcycles to premium vehicles and sports cars with high power density.